|

Ningbo Yoyo Foam Glass Co., Ltd.

|

pumie bar

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

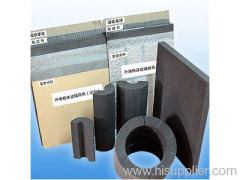

cellular bar

nonflammable

low thermal conductivity

non-moisture absorbing

In special cellular structure of numerous closed cells, foam glass is one of the best material to be used for low temperature heat insulation, with properties of light weight, low thermal conductivity, non-moisture absorbing, nonflammable, resistance to all chemical corrosive materials with exception of hydrogen fluoride, can be used in harsh conditions of extremely low temperature, underground, open-air, inflammatory, moist and corrosive.

Foam glass is mainly made from glass, mixed with foaming agent, in a process of heating and roasting in tunnel furnace, then annealed into bulk blocks, and cut into bricks or blocks in our sandard dimension.

Foam glass is also an excellent material for fire and vibration proof.

Typical application includes petrochemical industry, cold storage, underground engineering, ship-building and defence works as permanent heat insulation and cold preservation material.

Density of foam glass

We supply two types of blocks:

- High Density - 150 kg/m3

- Low Density - 120, 130 kg/m3

And we supply much more High Density blocks as building insulation material to the market in America and Europe.

Standard Dimension of foam glass blocks

Standard Dimension of foam glass blocks

- High Density:

- 610mm (24 inch) x 470mm (18.5 inch)

- Thickness: Max 160 mm ( 6.3 inch)

- Low Density:

- 610mm (24 inch) x 460mm (18.1 inch)

- Thickness: Max 180 mm ( 7.1 inch) Small white pieces of pumice bar is made of foam glasses and this is a very great material for cleaning swimming pool, chemicals, grills in bake, and etc.

- Cellular bar

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!